With the rapid development of building material technology, there are more and more types of glass. Basic lighting, permeability, safety needless to say, with higher performance and function of the glass is also emerging. As the core component of doors and Windows, what kind of glass can let users rest assured to start?

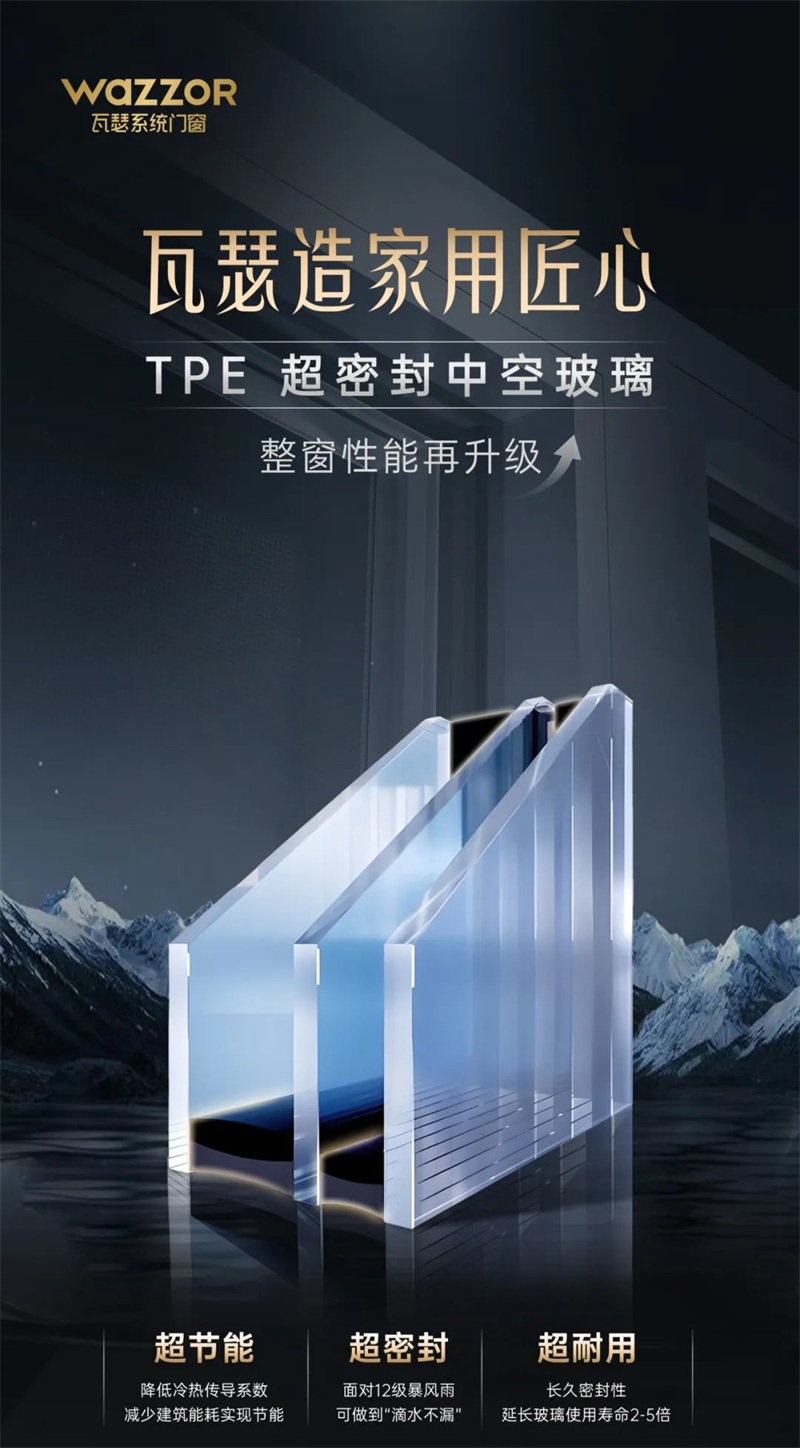

Wasser system doors and Windows new TPE super sealed insulating glass, using high-performance warm edge system, with "super energy saving, super sealing, super durable" three advantages, to achieve the whole window performance upgrade, to create a new benchmark of door and window quality!

What exactly is TPE?

First-class leading technology to break the industry blockade

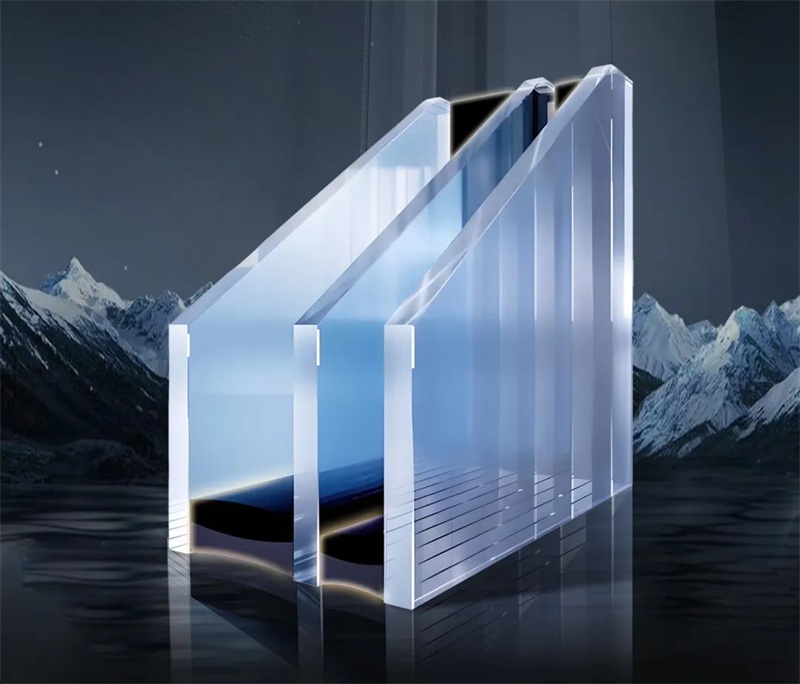

TPE full name: Thermo Plastic warm Edge, glass industry collectively referred to as: Thermo Plastic Space Sealant for Insulating Glass Unit, referred to as TPSS, Chinese acronym for insulating glass unit, "super sealed insulating glass", refers to thermoplastic warm edge spacer, is a new insulating glass sealing process.

TPE was independently developed by Beijing Tomorrow Star Glass Machinery Co., Ltd. in 2015, broke the technological monopoly of Europe and the United States in one fell fell, and was promoted and listed nationwide in 2021. Thermoplastic warm edge spacer, using special butyl adhesive mixed molecular sieve extrusion molding, replacing the traditional insulating glass metal and aluminum spacer medium, comprehensively improve the beauty of insulating glass, sealing, gas retention, service life and other properties.

TPE super sealed insulating glass

The whole window performance can be upgraded again

The continuous iteration and optimization of products, the continuous integration and concentration of resources and the high standard of process technology have been the basic guarantee of the quality service of Wasser system doors and Windows. In order to create a better use experience of doors and Windows, Wasser system doors and Windows officially introduced the technology and equipment of Beijing Tomorrow's star, launched the "TPE super sealed insulating glass", which can be assembled with Wasser's full range of products to meet the new needs of modern residential doors and Windows.

Ultra-energy saving

The common insulating glass on the market is used by adding metal aluminum spacer strips in the middle of two or more pieces of glass as the spacer cavity of the hollow layer, but because the aluminum spacer strips are easy to form a metal thermal bridge in the indoor and outdoor temperature difference convection, resulting in excessive heat loss of the glass. The Wasser TPE super sealed insulating glass replaces the aluminum strip with a thermoplastic warm edge partition, and its linear heat transfer coefficient is much lower than that of the ordinary aluminum partition strip, blocking the heat dissipation of the glass edge, thus improving the thermal insulation performance of the whole window.

With the improvement of people's quality of life, the comfort of the living environment is getting higher and higher. The warm side effect brought by Wasser TPE super sealed insulating glass is conducive to reducing the air convection and stabilizing the indoor temperature, blocking the heat loss of the house, creating a more comfortable indoor environment, reducing energy consumption and achieving energy saving.

superseal

There is another problem with the use of metal aluminum insulation glass, that is, the aluminum insulation and the original glass are "hard connected", do not have sufficient elasticity, cold heat conduction thermal expansion and contraction impact is easy to produce "breathing effect", which leads to butyl rubber overflow, argon leakage, glass fog, condensation and so on.

The thermoplastic warm edge spacer used by Wasser TPE super sealed insulating glass is directly extruded by special butyl adhesive mixed molecular sieve, and the consistency of the sealing material is better, and the chemical bonding with glass and silicone adhesive can form an intimate bond, making the insulating glass structure more stable and stronger bonding.

Its excellent compression, rebound and recovery characteristics ensure the stability of the insulating glass edge, and can flexibly adapt to frequent changes in external temperature and wind pressure. In addition, butyl adhesive material has strong water vapor and gas barrier ability, which is conducive to maintaining the sealing performance of insulating glass for a long time, and with inert gas, it can maximize the prevention of glass fog and dew, and can also be "watertight" in the face of 12 level storms.

ultra-durable

According to the relevant data, the quality of the edge seal is directly related to the sealing durability of the insulating glass, and the use of low water vapor and gas transmission of the sealant is the key. The thermoplastic warm edge spacer of Wasser TPE super sealed insulating glass has excellent water vapor and gas barrier ability, which can keep the internal air layer dry and effectively improve the sealing durability of insulating glass.

In addition, due to the excellent sealing performance of Wasser TPE super sealed insulating glass, blocking the infiltration of water vapor and gas, the argon filling capacity reaches 95%, far exceeding the industry standard of 85%. The annual leakage rate of argon gas of Wasser TPE super sealed insulating glass is only 0.08%, and the argon gas holding life is usually more than 25 years, which is far more than the traditional insulating glass of 10-15 years.

In the future, Wasser system doors and Windows will adhere to quality first, increase product research and development efforts, create high standards of doors and Windows products, provide consumers with better quality solutions for the whole house system doors and Windows, and contribute to the high-quality development of doors and Windows industry!