"The devil is in the details" - this design maxim from the renowned 20th-century architect Mies van der Rohe profoundly expresses the decisive role of details in quality. This concept is also perfectly interpreted in the product philosophy of Wazzorer System Doors and Windows. Just as Wazzorer firmly believes: True quality lies not only in the refinement on the surface, but also in the extreme pursuit of every detail. In an era that pursues efficiency, Wazzorer interprets the craftsmanship pursuit of high-end custom door and window brands with the "devilish details" behind the numbers.

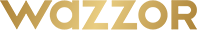

108 production processes for doors and Windows

With 108 production processes and 87 quality control nodes, the quality control system covers the entire chain, precisely measuring precision craftsmanship. Every aspect embodies the concept of "precision in the minute and dedication in the small". Wazzorer Super Factory has introduced eight powerful intelligent production equipment, leading the era of intelligent manufacturing 5.0. Every door and window is not only a functional carrier but also a home art piece that combines safety, aesthetics and durability.

25+ top-notch supply chain systems

Wazzorer has joined hands with over 25 global suppliers to build a top-notch supply chain system, empowering the quality gene with global resources. The adaptation of every hardware system and the selection of every sealing strip have all undergone strict screening and adaptation verification by the R&D team. This in-depth control over the supply chain enables Wazzorer to continuously drive the iterative upgrade of product performance.

0.01mm digital precise cutting

An error control of ±0.01mm is equivalent to one-tenth of the diameter of a human hair. Wazzorer System Doors and Windows has introduced the world's leading technology and equipment - the Yeelu SBZ630 integrated production equipment, with micron-level process standards, achieving digital precise cutting of 0.01mm. The forged cut surface produced is more exquisite, and the profile splicing is tight and seamless.

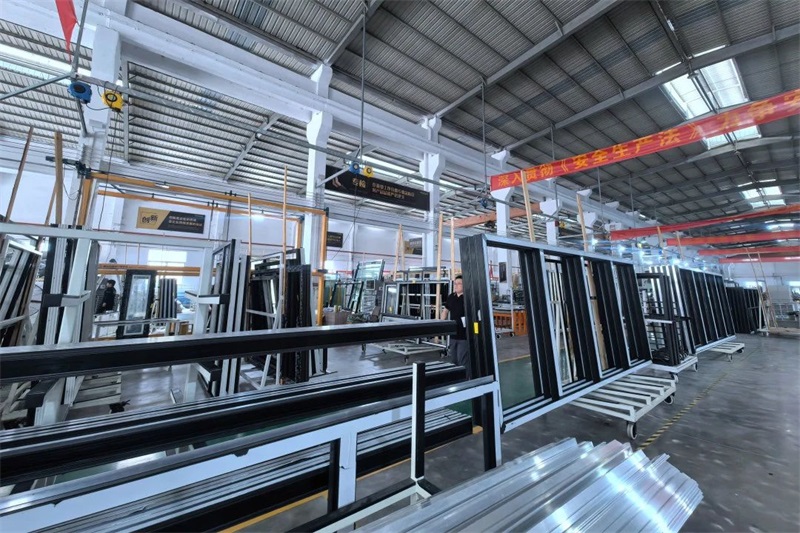

180-degree large circulation hardware opening and closing test

Durability is an important criterion for measuring the quality of hardware. The Sobinco Sobinco baseless handle equipped on the Wazzorer has passed strict tests in accordance with European standards such as EN13126-3. In the 180-degree cycle opening and closing function test, based on the full-scene actions of "locking - opening - locking - inward tilting - locking", it can achieve 20,000 high-intensity repetitive operations in accordance with European standards. Behind this figure lies Wazzorer's silent commitment to the quality of life for its users.

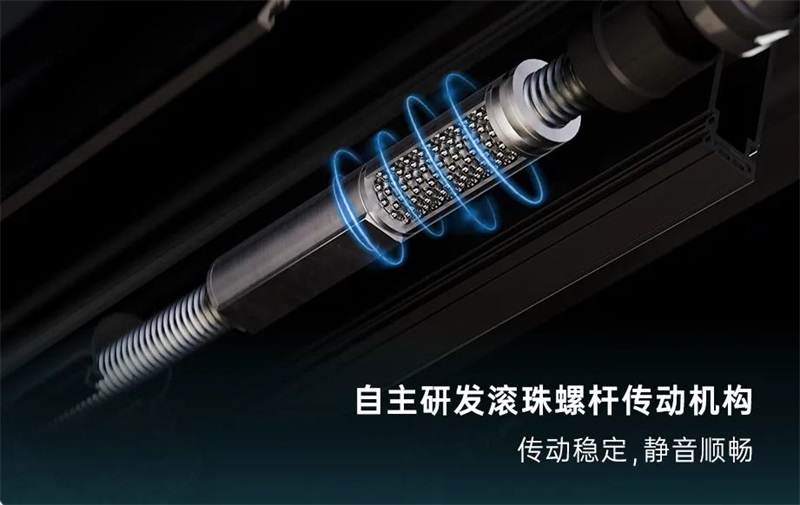

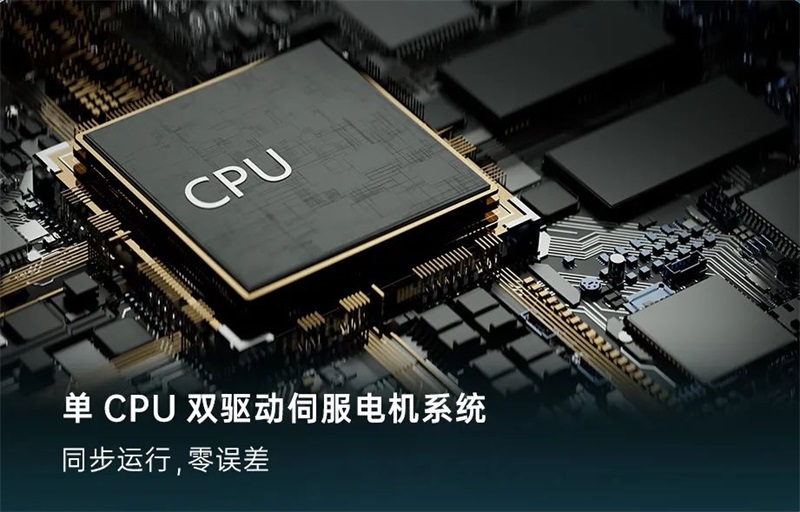

The operating sound of the lift window is less than 30dB

What's it like to have a decibel level below 30? Just the volume of a soft whisper. The sliding Windows on the market have long been criticized for the noise from the motor operation. The Wazzorr electric sliding balcony window features silent and efficient transmission, with an operating noise level below 30 decibels, which is even lower than the noise standard for sleeping environments.

25mm extremely narrow mid-top design

The core of minimalist doors and Windows lies not only in "narrowness" but also in "safety". The most ideal solution is to upgrade the performance while maximizing the frame size. The Wazzor 25SPV panoramic sliding door Narrows the middle straight visible surface to 25mm, breaking the heaviness of traditional doors and Windows and advancing to an ultimate wide view, achieving a dual breakthrough in aesthetics and mechanics.

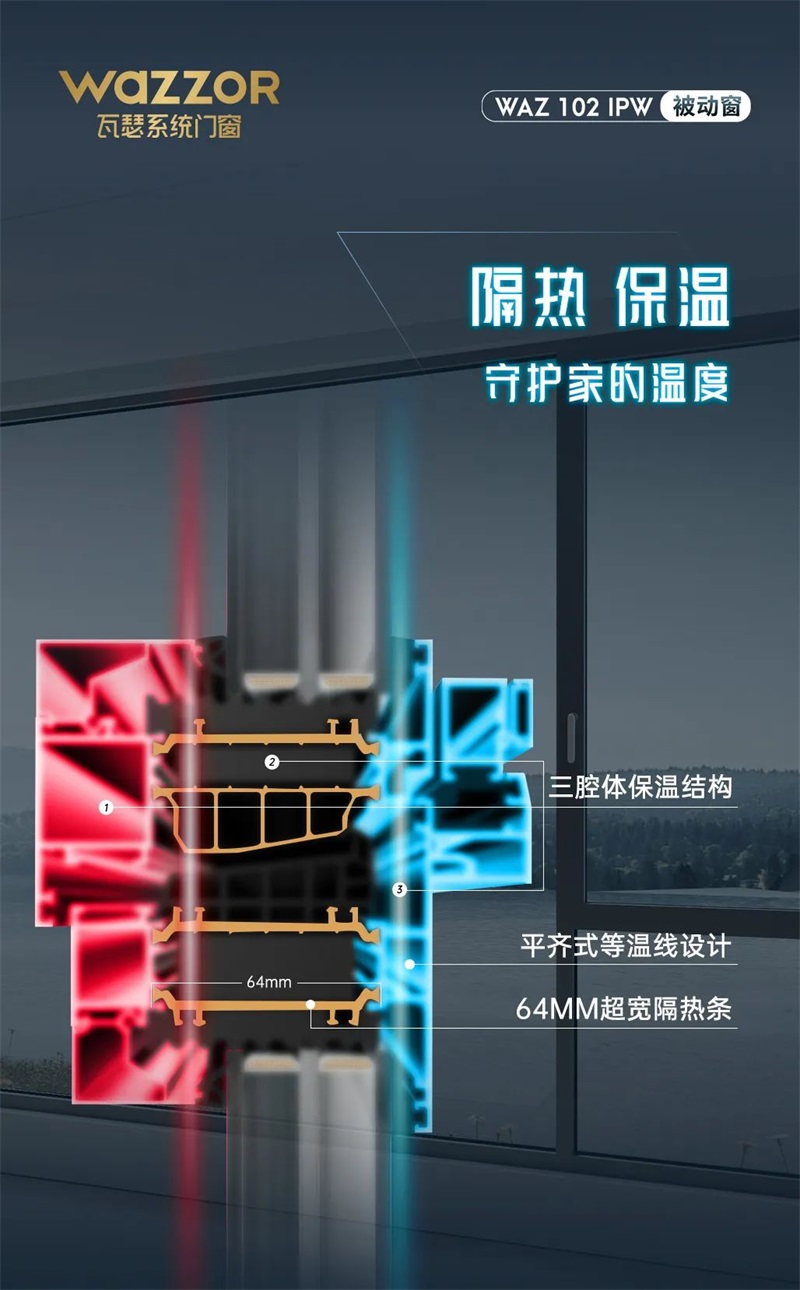

64mm ultra-wide thermal break

The 64mm ultra-wide thermal break strip is more than twice the size of the conventional thermal break strip, and its thermal insulation effect far exceeds that of similar products. Wazzor 102IPW passive window, designed for extreme climates, is equipped with a 64mm German Tylenow ultra-wide thermal insulation strip, with a K value of less than 0.79. It features passive near-zero energy consumption and builds a green building that maintains a constant temperature and saves energy.

Zero-break seamless welding rubber strip process

The Wazzor seamless welding rubber strip process, through seamless connection by injection molding, forms an integral frame structure, achieving a "0 break point" integrated seal. This effectively avoids the sealing failure problem caused by the interface of traditional rubber strips, reduces the penetration of air, moisture and noise, and doubles the sealing performance of the entire window.

43 standardized installation procedures

From measurement to production, from site entry to completion, Wazzor's "Wow Home" high-end decoration delivery system, with 43 standardized installation procedures, strictly controls every link of installation and delivery to ensure that every door and window is perfectly installed, allowing users to install with peace of mind and without any worries throughout the process. Wazzorer believes that "delivery" is not only the end of product implementation but also the starting point of lifelong service.

Details are silent, but quality endures forever. In both visible and invisible places, Wazzorer stubbornly refines the product details and craftsmanship, allowing the quality of doors and Windows to stand the test of time and creating a quiet and comfortable living space.