As the height of summer approaches, with temperatures above 35℃ persistently scorching the city, the phenomenon of glass self-explosion has once again come into the public eye. For families that use large glass Windows for sealing, they should enjoy a wide view and abundant natural light, but they are constantly facing safety concerns due to the potential risk of glass self-explosion. So, why does summer become a high-incidence period for the self-explosion of large glass window seals?

The core cause of glass self-explosion

Thermal stress: A potential threat caused by temperature differences

In hot summer, the temperature difference between the inside and outside of the glass under direct sunlight is relatively large, which can cause the glass to expand and contract asynchronously, forming thermal stress. When this stress exceeds the strength limit of the glass itself, it will cause self-explosion. However, large-sized glass, due to its large heating area and complex heat conduction path, has a more uneven distribution of thermal stress, and the risk of self-explosion increases accordingly.

Nickel sulfide impurities: An "unstable factor" inside glass

During the glass production process, trace amounts of nickel sulfide impurities are difficult to be completely avoided. At room temperature, these impurities are relatively stable. However, in the high-temperature environment of summer, nickel sulfide undergoes crystalline state changes and volume expansion, thereby triggering microcracks and causing self-explosion. This type of self-explosion has a distinctive "butterfly spot" feature. In the core area where the cracks converge, black spots formed by nickel sulfide impurities can usually be observed. In the industry, the self-explosion rate of tempered glass is generally between three and five per thousand, which is also within the range permitted by national standards.

Installation hazard: Details determine the safety of glass

Large glass window seals have extremely strict requirements for installation techniques. Surface damage such as scratches and bumps caused during handling or installation forms local stress concentration points, significantly reducing the strength of the glass. In addition, if the installation is not carried out in accordance with professional standards, it may also generate installation stress and leave hidden dangers of self-explosion.

Large glass window sealing can avoid risks

Choose ultra-white glass with fewer impurities

Ultra-clear glass, in the manufacturing process, uses high-purity raw materials and undergoes strict production techniques to effectively reduce the content of impurities such as nickel sulfide in the glass type. It has higher strength and excellent thermal stability, and can better withstand high summer temperatures and sudden temperature differences. Its self-explosion rate can be reduced to about one in a thousand. In addition, the ultra-clear glass has a light transmittance of 92% (while ordinary glass only has 85%), achieving crystal-level light transmission and nearly 100% visual restoration enjoyment, combining safety and appearance standards!

As the first in the industry, Wazzor System Windows has upgraded its entire product range with Low-e low-emissivity glass, TPE super sealing, and 6mm ultra-white glass, achieving stronger performance, exceeding standards, and delivering glass configurations far beyond those of the industry's Windows and doors, creating a high-performance window and door usage experience.

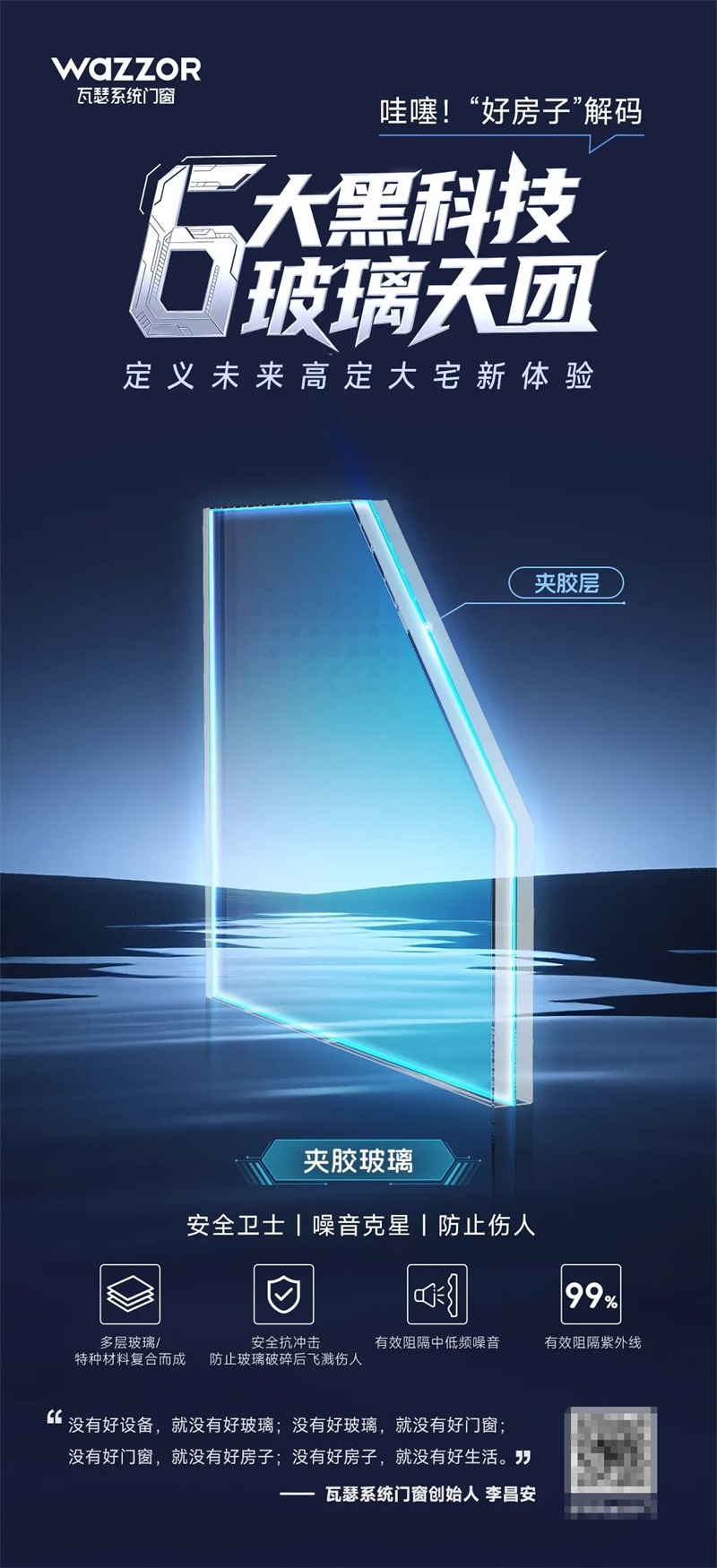

Select laminated glass with high safety

Safety is the most prominent feature of laminated glass. Between two or more pieces of glass, intermediate film materials such as PVB and SGP are sandwiched. This structure enhances the overall strength. Even in the event of a self-explosion, the glass fragments will be firmly adhered to the film, effectively preventing them from flying and injuring people. In addition, laminated glass performs exceptionally well in sound insulation. For large glass window sealing or high-rise applications, laminated glass is an important choice for enhancing safety levels.

Homogenize the glass and detonate it with an explosion

The principle of homogenization treatment is that after the glass is tempered, it is reheated in a homogenization furnace to around 260°C+10°C, and then maintained at a constant temperature for a certain period of time before being slowly cooled down. This process can enable potentially defective glass to "explode" in advance. For glass of intact quality, this treatment can promote the complete transformation of the α phase of nickel sulfide into the stable β phase at low temperatures, thereby significantly enhancing the safety of glass usage. Wazzor System Windows suggests that for large glass with a thickness of 10mm or more, homogenization treatment should be carried out to ensure safety to the greatest extent.

Strictly control on-site delivery to reduce glass breakage

Extreme caution must be exercised during transportation to avoid any mechanical damage such as scratches or dents on the glass surface. Before installation, the glass must be carefully inspected to prevent damage from becoming the starting point for future stress release, etc. In the installation project, standardized installation procedures are followed and every link of installation and delivery is strictly controlled. Wazzor's "Wow Home" high-end decoration delivery system, with 43 standardized installation procedures, strictly controls the installation and delivery to ensure that every door and window is perfectly installed, allowing users to install with peace of mind and without any worries throughout the process. Wazzor believes that "delivery" is not only the end of product implementation but also the starting point of lifelong service.

Attach importance to daily maintenance and inspection

Wazzor suggests that users regularly inspect the glass surface for cracks, scratches, bubbles, whether the edges are intact, and whether the sealing strips have aged, hardened, cracked or fallen off. If any abnormality is found, professional personnel should be contacted in time for assessment and handling.

High temperatures in summer are the key factor that triggers the spontaneous explosion of glass. For families choosing large glass window seals, safety is by no means a trivial matter. Only by scientifically selecting materials, strictly controlling delivery and insisting on regular inspections can a solid barrier for home safety be built.

Wazzor hopes for every window

It not only brings a broad view and bright sunlight

It can better safeguard the peace of mind and comfort of you and your family